CRUDE OIL TREATMENT

CRUDE OIL TREATMENT

Electrostatic Coalescers (also referred to as Electrostatic Treaters, Crude Oil Dehydrators and Desalters) are used to separate moderate levels of produced water (typically up to 10%) from crude oil and are used to lower product water content to typically 0.5% for offshore applications and as low as 0.1% for refinery applications. Dewatering is necessary to avoid corrosion in pipelines and downstream processing equipment, to reduce bulk fluid transportation costs and, to meet refinery feedstock water content and salt content requirements. Electrostatic Coalescers are used where gravity separation alone cannot achieve the desired product specification.

Fraser Uniquip offer a wide range of Electrostatic Coalescer configurations utilising proven, reliable, operationally simple and cost effective AC technology with ancillary systems including :-

- 2 or 3 grid arrangements

- Multi stage arrangements

- Single or Double volt electrical connections

- FPSO/FSO/FPU designs

- Sand/Sludge removal systems

- Hazardous Area Certified 100% impedance reactor/transformer technology

- Mixing Valves, Static Mixers and Injection tee’s

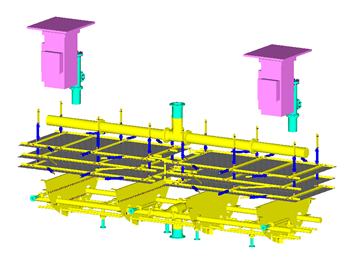

Typical 3 Grid FPSO Electrostatic Coalescer Internal Arrangement

Principle of Operation

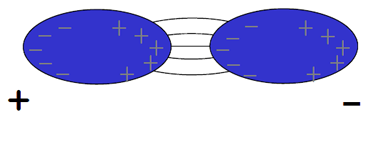

Water Droplets in an Electrostatic Field

Upon exposure to an intense electrostatic field, water droplets dispersed in oil will elongate from their original spherical shape to an oval shape with separated positive and negative charges (Dipole). The Dipole exhibits a magnet type polarity with the polarised ends of the droplets being attracted to each other. Molecular vibration causes coalescence to form larger water droplets which separate more easily by gravity from the oil.

Water Droplets prior to Energising Electrostatic Field

The effects on the water droplet arise from the very different dielectric properties of the conductive water droplets dispersed in the crude oil. Water droplets have a permittivity that is much higher than the surrounding oil. When an uncharged droplet is subjected to an AC electric field the field will polarise the droplet creating an electric field around the droplet to counteract the external field. As the water droplet is very conductive the induced charges will reside on the surface. The droplet has no net charge but one positive and one negative side. Inside the droplet the electric field is zero.

Water Droplets inside an Electrostatic Field

Since non crystalline salt is only carried in produced water the removal of water also results in the removal of salts (Desalting). Depending on the application and required product specification multiple stages of Electrostatic Coalescers may be required.